AGT Robotics

Robotic Welding for Structural Steel

Robotic Welding for Structural Steel

AGT Robotics is a leader in robotic automation, delivering cutting-edge solutions that optimize productivity, enhance precision, and improve workplace safety. Designed for fabricators handling high-mix, low-volume production, AGT Robotics provides innovative systems that streamline operations and maximize efficiency.

Read on to learn more and see videos of robotic welding and layout system from AGT Robotics, and contact us today if you’d like to request a quote on a leveling or deburring system for your business.

BeamMaster – Robotic Welding

The BeamMaster by AGT Robotics is an advanced robotic welding system designed specifically for structural steel fabrication. Engineered to handle high-mix, low-volume production, the BeamMaster automates beam welding with minimal programming and maximum efficiency. Its intelligent vision system allows it to identify and adapt to complex geometries, eliminating the need for manual fixture adjustments. By reducing cycle times and labor dependency, the BeamMaster increases productivity, enhances weld quality, and improves overall shop efficiency. This turnkey solution is ideal for fabricators looking to streamline operations while maintaining the flexibility required for custom and large-scale projects.

Why Choose AGT Robotics?

-

Automates High-Mix, Low-Volume Welding – Unlike traditional robotic welding systems, the BeamMaster is designed for custom and complex structural components, eliminating the need for dedicated fixtures.

-

Intelligent Vision System – Equipped with adaptive laser scanning, the system identifies part geometries and automatically adjusts welding paths, ensuring precise and consistent welds every time.

-

No Programming Required – The BeamMaster uses Smart System technology, automatically generating weld paths based on CAD data, significantly reducing setup time and eliminating the need for specialized robotic programming skills.

-

Increases Productivity & Reduces Costs – By automating beam welding, the BeamMaster reduces manual labor requirements, cuts down on rework due to human error, and boosts overall shop throughput.

-

Flexible & Scalable – Whether you’re handling beams, columns, trusses, or box sections, the BeamMaster adapts to different shapes and sizes, making it the ideal solution for custom fabrication and high-variation projects.

-

Turnkey Solution – Designed for easy integration, the BeamMaster fits seamlessly into existing production workflows, helping fabricators scale their operations without major infrastructure changes.

For a quote on a BeamMaster for your business, contact us today. We look forward to helping you determine the best machine for your unique process!

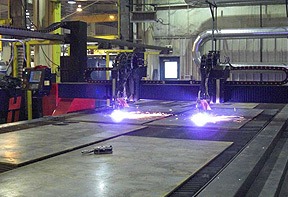

LayoutMaster – Layout System

The LayoutMaster by AGT Robotics is a game-changing robotic marking and layout solution designed to streamline structural steel fabrication by eliminating manual layout processes. Here’s why it’s the ideal choice for fabricators looking to increase accuracy and efficiency:

- Automates Complex Layout Tasks – The LayoutMaster replaces manual scribing with high-speed robotic marking, reducing errors and significantly improving workflow efficiency.

- No More Manual Measuring – With precise laser scanning and CAD-based automation, the system ensures perfectly marked positions for holes, cutouts, welding points, and part placements—eliminating rework caused by human error.

- Handles High-Mix, Low-Volume Production – Unlike traditional layout methods that require extensive manual labor, the LayoutMaster is designed for variable parts, unique designs, and custom fabrication, making it a perfect fit for structural steel projects.

- Seamless Integration with CAD & BIM – The system imports CAD/BIM files directly, automatically generating the most efficient layout markings without the need for manual input, saving hours of labor per project.

- Increases Throughput & Reduces Costs – By automating layout and marking, the LayoutMaster drastically reduces production time, minimizes material waste, and lowers labor costs—resulting in a more profitable and scalable operation.

- Works on Beams, Plates & More – Whether it’s beams, columns, trusses, or large plates, the LayoutMaster adapts to different part geometries and materials, making it a versatile solution for structural steel shops of all sizes.

By implementing the LayoutMaster, fabricators can eliminate tedious manual layout work, increase accuracy, and accelerate project timelines, ensuring a more efficient, cost-effective, and competitive fabrication process.

For a quote on a LayoutMaster, contact us today! We look forward to serving you.