Three Easy Solutions That Will Save Your Shop Money

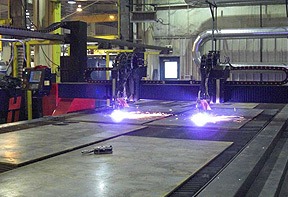

We’re always excited about products that increase efficiency and improve production processes. Better technology can be a game changer for a fabrication company by reducing scrap materials and creating efficiencies that save time and money.

Read on to learn about three great solutions that can give your operation an advantage when it comes to cutting, design and fabrication. If you’d like to see how this kind of software and equipment could impact your business, contact us today to learn more.

- Metamation CAD/CAM Software

Metamation is the industry leader in CAD/CAM software for sheet metal designers. With 2D and 3D CAD features, you can quickly and easily draw your own parts or directly import various 2D or 3D file types with MetaCAD. Advanced animation features allow you to preview your models or assemblies, ensuring flawless design of all parts and products.In addition, Metamation’s CAD/CAM nesting software includes a feature-packed nesting engine with algorithms for all of your punching or cutting machines, designed to help you get the most out of your raw materials based on your available demand. Not only can this program save you time, it can save you money by eliminating waste.

- EHRT Nesting Software

PunchPro nesting software works hand-in-hand with EHRT CNC punching machines to give metal fabricators a competitive edge. With custom animations and a Microsoft Windows based operating system, machinists can visualize parts before they go into production, make necessary adjustments with ease, and nest parts to maximize raw materials.Perfect for shops that work with steel and aluminum bar stock as well as copper bus bar, PunchPro software is simple to implement. Another unique benefit PunchPro offers is that it allows multiple machine operators and office personnel to access to the same database, ensuring processes run smoothly and changes are easily communicated before work is performed.

- Automec Retrofit CNC Backgauges

Automec’s powerful systems allow you to add an automated backgauge to almost any existing press brake, thereby simplifying operation and reducing human error. Best of all, once implemented, these systems use digital photos and 2D graphics to make forming easier and more efficient.Their PC800 control system offers 2D graphical representation of the part forming sequence and allows you to use JPEG photos of your tooling and work piece to give the operator a better visual of each bend. It’s as simple as downloading photos from your camera to your desktop computer! With a Microsoft Windows based operating system, the PC800 Control System is simple to use and easy to learn – saving you time and money when it comes to training and operation.

Technology can have a major impact on your metal fabrication business, so please contact us today if you’d like to learn more. Our team is always available to answer questions and provide pricing on new technology that will help your business become more successful!