Global Compliance at Fingertips: How Automated Machine Tending Systems are Standardizing Manufacturing

In the constantly evolving landscape of manufacturing, the push towards automation and global standardization has never been more prominent. Automated Machine Tending (AMT) systems are at the forefront of this movement, offering a bridge between manual labor and full automation. Among the players propelling the standardization and global compliance of AMT systems, AutoTend™ by Mid Atlantic Machinery Automation emerges as a notable solution. This blog explores how AMT systems like AutoTend™ are catalyzing global compliance and standardization in the manufacturing sector, thus enabling manufacturers to attain new pinnacles of efficiency and quality control.

Steering Towards Global Compliance and Standardization

The essence of global compliance and standardization lies in creating a unified set of criteria that ensures quality, safety, and efficiency across various manufacturing landscapes. One of the significant strides towards this goal is the establishment of ISO 21919-1:2019 standard, which delineates the interfaces between automated machine tending devices and production machines, thus establishing a framework for seamless interaction between these entities1.

AutoTend™: A Beacon of Standardization

AutoTend™ by Mid Atlantic Machinery Automation is a quintessential example of how AMT systems are embracing and promoting global standardization. Designed to tackle repeatable tasks with consistency and efficiency, AutoTend™ facilitates the automation of machine tending processes, ultimately bolstering the bottom line of manufacturing operations2.

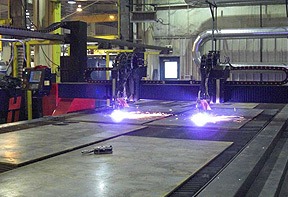

The allure of AutoTend™ lies in its capability to integrate with a myriad of manufacturing processes effortlessly. Whether it’s press brakes, deburring machines, CNC machines, or quality inspection machines, AutoTend™ provides a standardized interface that once installed, can control and manage a wide variety of machines in a manufacturing setup2.

Moreover, the AutoTend™ solution aids in significantly reducing labor costs and minimizing scrap, exemplifying how automation can drive cost-efficiency and quality improvement in manufacturing3.

Bridging the Global Standardization Gap

Companies like Universal Robots are also playing a pivotal role in this standardization journey. Their commitment towards democratizing automation is evident through their efforts to integrate their products into diverse manufacturing environments, thus fostering standardization and efficiency4.

Similarly, the modular automation approach, as seen in AutoTend™, showcases a less costly and more efficient alternative to larger solutions, with up to 50% more machine uptime and up to 50% less cost. It also necessitates up to 20% lower life cycle management investment, which is a substantial saving for manufacturers5.

Conclusion

The pathway towards global compliance and standardization in manufacturing through Automated Machine Tending systems is a collaborative effort among various stakeholders. Systems like AutoTend™ are not only propelling the industry towards a standardized operational framework but are also showcasing the boundless potentials that automation holds in revolutionizing manufacturing processes. Through continuous innovation and adherence to global standards, the manufacturing domain is well on its way to achieving a harmonized operational landscape that promises enhanced efficiency, safety, and quality control.