How Mid Atlantic Machinery’s AutoTend™ Tending Systems Are Addressing the Labor Shortage in Manufacturing

How Mid Atlantic Machinery’s AutoTend™ Tending Systems Are Addressing the Labor Shortage in Manufacturing

The manufacturing industry is experiencing a severe labor shortage, and companies are grappling with how to maintain productivity and control costs. Mid Atlantic Machinery Automation is stepping in with an innovative solution—AutoTend™ machine tending systems. These automated systems are designed to increase efficiency, minimize manual labor, and help companies overcome the ongoing shortage of skilled workers. But how exactly are AutoTend™ machine tending systems making an impact?

What is AutoTend™ Machine Tending Systems?

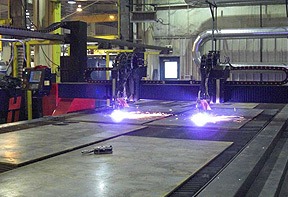

AutoTend™ machine tending systems are state-of-the-art automation solutions that take over repetitive, labor-intensive tasks in manufacturing environments. By utilizing advanced robotics and user-friendly software, AutoTend™ machine tending systems enable companies to automate key production processes, traditionally requiring human oversight. This automation leads to enhanced operational efficiency, improved product quality, and scalability—all while reducing the dependence on manual labor.

The Labor Shortage Challenge

The manufacturing industry faces a critical shortage of skilled labor. In fact, Deloitte predicts that by 2030, the U.S. manufacturing sector could have as many as 2.1 million unfilled positions. This labor gap is creating significant challenges for businesses, resulting in slower production times, reduced profitability, and the potential loss of competitiveness.

How AutoTend™ Machine Tending Systems Help Combat Labor Shortages

- Boosting Productivity

One of the primary benefits of AutoTend™ machine tending systems is their ability to perform the work of multiple employees without fatigue. By automating tasks such as material handling, loading and unloading parts, and quality inspections, AutoTend™ machine tending systems frees up human workers to focus on more complex, high-value tasks. This helps businesses maintain—and often increase—productivity, even with fewer employees on hand.

- Reducing Worker Burnout

With the pressure on current employees to meet increased demand, burnout and turnover are growing concerns. AutoTend™ machine tending systems alleviate some of this burden by handling repetitive, physically demanding tasks. This leads to better employee morale, fewer costly mistakes, and a decrease in workplace accidents caused by overworked staff.

- Closing the Labor Gap with Automation

Finding skilled workers is becoming increasingly difficult, but automation is helping to fill that hole. AutoTend™ machine tending systems offer a reliable, efficient, and scalable solution to keep production moving. Unlike human workers, AutoTend™ machine tending systems can operate 24/7, allowing businesses to maintain their output levels—even during periods of labor shortage.

Why Choose AutoTend™ Machine Tending Systems?

- Seamless Integration

AutoTend™ machine tending systems are designed to integrate smoothly into existing equipment. Whether you’re looking to automate one step or an entire workflow, these systems can be tailored to fit your needs without requiring a complete operational overhaul.

- Cost-Effective Automation

While automation can sometimes seem expensive, AutoTend™ machine tending systems offer a cost-effective solution. By reducing the need for additional labor and improving overall productivity, these systems offer long-term savings that quickly offset the initial investment. AutoTend™ machine tending systems don’t take days off or call off for work.

- Customizable Solutions

Every manufacturing environment is different, and AutoTend™ machine tending systems are highly adaptable. Whether your business requires automation for press brake tending, finishing machine tending, stamping, PEM insertion machine tending, and more, these systems can be built to meet your specific needs.

Ask Yourself: Can AutoTend™ Machine Tending Systems Benefit Your Business?

- What tasks in your production line are creating bottlenecks or slowing down output?

Automation could help streamline these processes and keep your operation running smoothly.

- Are you spending too much on temporary labor or overtime?

AutoTend™ machine tending systems can help reduce those costs by handling tasks that no longer require a human worker.

- Would a more efficient, less stressed workforce improve your bottom line?

Automation can reduce employee burnout, leading to greater retention and fewer costly disruptions in production.

The labor shortage in manufacturing presents a significant challenge, but businesses don’t have to let it limit their growth. With Mid Atlantic Machinery Automation’s AutoTend™ machine tending systems, you can leverage automation to increase productivity, reduce costs, and ensure your operations run smoothly—even when skilled labor is scarce. By integrating AutoTend™ machine tending systems into your manufacturing process, your business will be better equipped to thrive in today’s competitive landscape.