How Robotics is Transforming the Fabrication Industry

Robotics is having a profound impact on the fabrication industry, leading to significant transformations in the way products are designed, manufactured, and assembled. This transformation is driven by the convergence of various technologies, including robotics, artificial intelligence, and automation. Here are some ways in which robotics is reshaping the fabrication industry:

- Increased Efficiency and Precision: Robotics systems, such as industrial robots and automated machinery, can perform repetitive tasks with high precision and speed. This ensures consistent quality and reduces errors in the fabrication process. Robots can work around the clock without the need for breaks, leading to improved productivity.

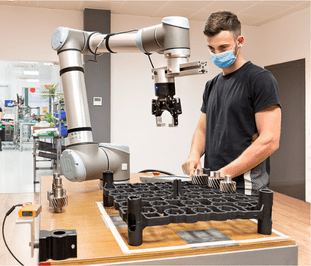

- Flexibility in Manufacturing: Collaborative robots (cobots) and advanced robotic arms are increasingly used in fabrication to handle a wide range of tasks. These robots can be easily reprogrammed and adapted to different processes, allowing for greater flexibility in manufacturing. This is especially valuable in industries where product variations and customization are common.

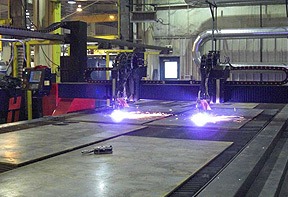

- Improved Safety: Robots can be employed in tasks that are hazardous to humans, such as welding, cutting, or handling heavy materials. This enhances worker safety and reduces workplace injuries. Collaborative robots, in particular, can work alongside humans, further improving safety and allowing workers to focus on more complex, creative tasks.

- Quality Control and Inspection: Robotics, combined with machine vision systems, is used for quality control and inspection in the fabrication industry. Robots can identify defects, measure precise dimensions, and ensure that products meet the desired specifications, helping to maintain high-quality standards.

- Enhanced Product Design and Prototyping: 3D printing and additive manufacturing technologies, which are closely related to robotics, have revolutionized product design and prototyping. These technologies allow for the rapid and cost-effective production of prototypes and custom parts, enabling designers to iterate and test ideas more efficiently.

- Reduction in Labor Costs: While automation in the fabrication industry does replace some jobs, it also creates new opportunities for skilled workers who are needed to operate, program, and maintain robotic systems. Overall, automation can lead to cost savings for manufacturers by reducing labor costs.

- Increased Productivity: Automation and robotics can significantly boost productivity in the fabrication industry. By streamlining processes and eliminating bottlenecks, manufacturers can produce more products in less time.

- Improved Supply Chain Management: Robotics and automation also play a crucial role in supply chain management. Autonomous mobile robots (AMRs) are used to transport materials and components within a manufacturing facility, optimizing the flow of goods and reducing lead times.

- Sustainability: Robotic systems can be programmed to optimize energy usage and resource consumption, contributing to more sustainable manufacturing practices. By reducing waste and improving efficiency, fabrication processes become more environmentally friendly.

- Industry 4.0 Integration: The integration of robotics and automation with the principles of Industry 4.0, including the Internet of Things (IoT) and data analytics, enables real-time monitoring and data-driven decision-making in the fabrication industry. This leads to better resource utilization, predictive maintenance, and improved overall efficiency.

In conclusion, robotics is transforming the fabrication industry by enhancing efficiency, flexibility, safety, and quality, while also contributing to advancements in product design and sustainability. As technology continues to evolve, we can expect further innovations in this field, leading to even more significant changes in the way products are fabricated. For more information contact us today!