Precision Unveiled: The Impact of Automated Machine Tending on Accuracy and Consistency

In a world where precision is paramount, modern manufacturing and fabrication outfits are continually seeking technological interventions to fine-tune their operations. Among the game changers is the adoption of Automated Machine Tending Systems (AMTS). These systems are not merely about reducing human intervention; they’re about significantly enhancing accuracy and consistency in production processes. Here’s how:

1. Reduced Human Error:

Human involvement, while indispensable, often brings along a margin of error. Whether it’s misalignment of parts or inconsistencies in loading and unloading, the potential for error is a reality. Automated machine tending systems step in to mitigate these discrepancies by performing repetitive tasks with precision, each time and every time. Not to mention Automated Machine Tending systems don’t have “Super Bowl Mondays”, they show up ready and don’t call in sick.

2. Enhanced Process Consistency:

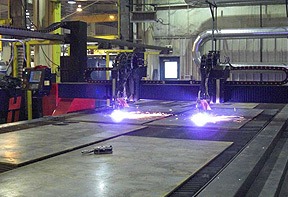

Consistency is the hallmark of quality in manufacturing. AMTS ensure that each operation is performed identically, irrespective of the hour or the day. This level of consistency is particularly beneficial in parts loading and unloading tasks, ensuring product and process consistency across various applications like grinding, milling, and welding1.

3. Precision in Repetitive Tasks:

The ability of AMTS to perform repetitive tasks with an unmatched level of precision is a boon to manufacturers and fabricators. By handling tasks like parts loading and unloading with exactitude, these systems contribute to the overall accuracy of the production process.

4. Improved Quality Control:

The precision and consistency offered by automated machine tending lead to improved quality of products. When each part is precisely machined and accurately tended, the resultant product quality is significantly enhanced, which in turn maximizes throughput and minimizes waste2.

5. Programmable Accuracy:

Automated systems can be programmed to meet the specific accuracy requirements of different tasks. This flexibility allows for the fine-tuning of operations to achieve the desired level of accuracy and consistency.

6. Real-time Monitoring and Feedback:

AMTS equipped with sensors and monitoring systems provide real-time feedback, allowing for immediate adjustments to maintain accuracy and consistency. This proactive approach ensures that any deviations from the desired standards are promptly corrected.

7. Data-Driven Insights:

The data collected by AMTS provide invaluable insights into the operational accuracy and areas of improvement. By analyzing this data, manufacturers can further refine their processes to attain a higher degree of accuracy and consistency.

The adoption of Automated Machine Tending Systems is a stride towards perfection in manufacturing and fabrication domains. By automating the tending processes, manufacturers are not only propelling their productivity but are significantly elevating the accuracy and consistency, which are critical for meeting the ever-evolving market demands and standards. For more information contact us today!