The Evolution of TRUMPF Machinery

The Evolution of TRUMPF Machinery: A Legacy of Innovation and Precision

When it comes to the world of industrial manufacturing, few names are as iconic as TRUMPF. With over a century of expertise in the field, TRUMPF has established itself as a global leader in machine tools, laser technology, and electronics. This world-renowned company also has a long history supporting their success.

Founded in 1923 by Christian Trumpf, along with two partners acquired the mechanical workshops of Julius Geiger GmbH in Stuttgart. The company initially focused on flexible shafts, which were only produced for dental and printing requirements. Upon the development of the motorized drive, they were began being manufactured and sold for industrial purposes. The ability to adapt to changing market needs would become a hallmark of TRUMPF’s business strategy.

By the 1930s, TRUMPF expanded its product line to include motorized hand shears, marking the company’s first foray into machine tools. This shift laid the groundwork for TRUMPF’s future in high-precision machinery. The 1950s saw the introduction of stationary nibbling machines, which revolutionized sheet metal processing and further established TRUMPF as a leader in the field.

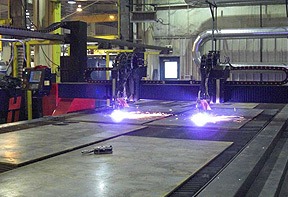

One of the most significant milestones in TRUMPF’s history when they created a laser development department in 1971 for solid state lasers. Then in 1979 they introduced entered the world of laser technology with the Trumatic 180 laser press combination punch laser machine. This innovation not only enhanced precision in metal cutting but also opened new avenues for the use of laser technology across various industries, including automotive, aerospace, and electronics.

The 1980s and 1990s were marked by rapid global expansion and technological advancements for TRUMPF. The company established subsidiaries in key markets, including the United States, Japan, and China. During this period, TRUMPF also introduced advancements in punching and bending technology, further solidifying its reputation as an industry leader.

Today, TRUMPF continues to lead the way in industrial manufacturing with cutting-edge innovations in laser technology, smart factory solutions, and additive manufacturing. The company’s commitment to research and development ensures that it remains at the forefront of technological advancements, driving the future of the manufacturing industry.

As TRUMPF looks to the future, the company is focused on digitalization and sustainability. The advent of Industry 4.0 and smart manufacturing solutions positions TRUMPF to continue its legacy of innovation. With a strong emphasis on reducing environmental impact and increasing efficiency, TRUMPF machinery is set to play a crucial role in the next generation of manufacturing.

The history of TRUMPF machinery is a testament to the company’s ability to innovate and adapt to the ever-changing demands of the industrial world. From its humble beginnings in a small workshop to becoming a global powerhouse, TRUMPF has consistently pushed the boundaries of what’s possible in machine tools and laser technology. As we look ahead, TRUMPF’s commitment to excellence ensures that it will continue to be a driving force in the manufacturing industry.