-

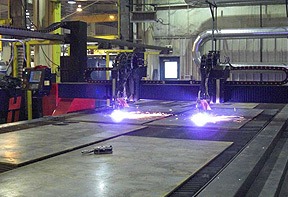

The Future of Fabrication: A Look Ahead

In conclusion, the future of fabrication holds great promise, with advancements in technology and materials enabling more efficient, sustainable, and customizable production. These developments will impact a wide range of industries, from aerospace and healthcare to consumer goods and construction, and will continue to shape the way we design and produce products in the coming years. Read More -

The Cost Efficiency Catalyst: Unveiling the Economic Advantages of Automated Machine Tending

In the fiercely competitive landscape of manufacturing and fabrication, cost-efficiency is a linchpin for sustainability and growth. The advent of Automated Machine Tending Systems (AMTS) has emerged as a formidable ally for enterprises striving to trim operational costs while enhancing productivity. Here’s an in-depth look at how AMTS are redefining cost-efficiency for modern manufacturers and… Read More -

Precision Unveiled: The Impact of Automated Machine Tending on Accuracy and Consistency

In a world where precision is paramount, modern manufacturing and fabrication outfits are continually seeking technological interventions to fine-tune their operations. Among the game changers is the adoption of Automated Machine Tending Systems (AMTS). These systems are not merely about reducing human intervention; they’re about significantly enhancing accuracy and consistency in production processes. Here’s how:… Read More -

Sustainable Manufacturing: Challenges and Opportunities

Sustainable manufacturing, also known as green manufacturing or eco-friendly manufacturing, is a concept that focuses on producing goods while minimizing negative environmental impacts and maximizing economic and social benefits. It involves the integration of environmental, economic, and social considerations into the manufacturing process.

Read More -

Enhanced Productivity Through Automated Machine Tending

Automated machine tending systems, which are deployed to oversee and manage machines or processes, are increasingly being adopted in the manufacturing and fabrication sectors. They contribute to enhanced productivity through several avenues: Increased Machine Uptime: Automated machine tending reduces the downtime of machines as they spend less time idle. The continuous operation improves the Overall… Read More