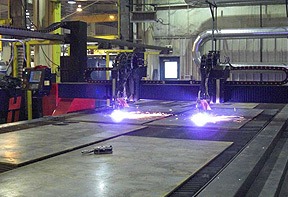

US Metal Crafters Invested in a 2D and 3D Combined System to Increase Speed and Accuracy

US Metal Crafters, based in Archdale, NC, invested in a 2D and 3D combined system to increase speed and accuracy to maximize their product flow. They were originally using manual tools such as calipers, protractors, and tape measures to inspect parts.

Larger and more complex parts were both difficult and very time-consuming to check so they began researching flow improvement and QA tools online to find a solution. They found the answer and landed on the InspecVision Planar system to fit their need. US Metal Crafters has been able to cut down their inspection time on each part by nearly 75%.

The entire US Metal Crafters team agree that it wasn’t difficult to justify the investment when they took into account the speed, accuracy and credibility it gave them. “It has been a great sales closing tool for new customers!”

Click the below to read the full Case Study and learn what an InspecVision Machine can do for your shop!