Safeguarding the Shop Floor: How Automated Machine Tending Bolsters Operational Safety

In the challenging environments of manufacturing and fabrication, ensuring the safety of personnel is paramount. Automated Machine Tending Systems (AMTS) have emerged as a significant ally in fostering safer work environments. Here’s an exploration of how these ingenious systems are bolstering safety:

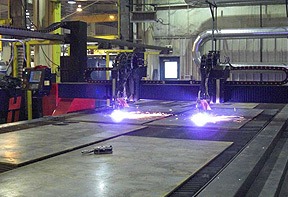

- Reduced Human Interaction with Hazardous Areas:

AMTS significantly minimize the need for human workers to interact with hazardous areas, thus reducing the likelihood of accidents. By handling dangerous tasks like parts loading and unloading or working with heavy machinery, automated systems ensure that workers are kept at a safe distance.

- Predictable and Controlled Movements:

The precise and controlled movements of automated systems are predictable, reducing the chances of unexpected incidents that could lead to injuries.

- Elimination of Repetitive Strain Injuries:

Repetitive, mundane tasks often lead to repetitive strain injuries among workers. Automated machine tending takes over these tasks, thus eliminating the risk of such injuries.

- Enhanced Monitoring and Real-Time Alerts:

Modern AMTS come equipped with sensors and monitoring systems that provide real-time feedback on the operational environment. This feature allows for immediate detection and alerting of any safety issues, ensuring prompt intervention.

- Reduced Fatigue-Related Errors:

Unlike humans, machines do not experience fatigue. By handling continuous operations, AMTS ensure that fatigue-related errors, which could compromise safety, are significantly reduced.

- Improved Workspace Organization:

Automated systems contribute to a more organized and clutter-free workspace, which in turn minimizes the chances of accidents due to tripping or falling.

- Compliance with Safety Standards:

AMTS are designed to comply with stringent safety standards, ensuring that operations are carried out within the defined safety protocols, thereby enhancing overall operational safety.

- Data-Driven Safety Enhancements:

The data collected by AMTS can be analyzed to identify potential safety hazards and to develop strategies for mitigating these risks.

The integration of Automated Machine Tending Systems is more than just a technological upgrade; it’s a substantial step toward creating safer manufacturing and fabrication environments. The safety enhancements brought about by AMTS not only protect the workforce but also contribute to creating a conducive and efficient operational milieu.

Dive deeper into the safety realm of automated machine tending in our comprehensive exploration and discover how embracing automation can be a pivotal move towards a safer, more efficient manufacturing landscape. For more information contact us today!