The Future of Fabrication: A Look Ahead

The future of fabrication is an exciting and rapidly evolving field that encompasses a wide range of technologies and processes. As we look ahead, several key trends and developments are likely to shape the future of fabrication:

-

Additive Manufacturing (3D Printing): Additive manufacturing, often referred to as 3D printing, continues to advance and expand its capabilities. It is increasingly used to create complex and customized parts across various industries, from aerospace to healthcare. New materials and printing techniques are being developed, enabling the production of stronger and more functional parts.

-

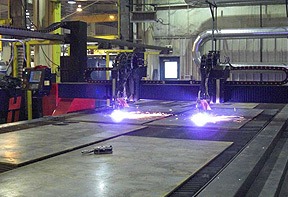

Digital Fabrication: Digital fabrication technologies, such as Computer Numerical Control (CNC) machining and laser cutting, are becoming more accessible and affordable. These technologies allow for precise and automated production of parts and products, making them ideal for small-scale manufacturing and rapid prototyping.

-

Generative Design: Generative design software uses algorithms to create optimal product designs based on specified parameters. This approach can reduce material usage and optimize structural integrity. It is likely to play a significant role in the future of fabrication, leading to more sustainable and efficient products.

-

Smart Manufacturing and Industry 4.0: Industry 4.0 is the concept of the “smart factory,” where automation, data analytics, and the Internet of Things (IoT) are integrated to optimize manufacturing processes. This will enable real-time monitoring and control, leading to improved efficiency, reduced downtime, and cost savings.

-

Bioprinting and Organ Fabrication: In the field of healthcare, bioprinting is making significant strides. Researchers are working on printing functional tissues, organs, and even human skin. The potential for personalized medicine and organ transplants is enormous, and this technology has the potential to revolutionize healthcare.

-

Sustainable Materials and Processes: With growing environmental concerns, there is a strong focus on sustainable materials and fabrication processes. Researchers are exploring biodegradable materials, as well as the use of recycled and renewable resources to reduce the environmental impact of manufacturing.

-

Nanotechnology: The use of nanomaterials and nanoscale fabrication techniques is becoming increasingly important. Nanotechnology allows for the creation of extremely small and precise structures, with applications in electronics, medicine, and many other fields.

-

5G and Edge Computing: The implementation of 5G networks and edge computing will enhance connectivity and enable real-time data processing in fabrication processes. This will improve remote monitoring and control of manufacturing operations.

-

Customization and Personalization: Fabrication technologies are enabling mass customization, where products can be tailored to individual preferences. This trend is seen in industries such as fashion, footwear, and consumer goods.

-

Robotics and Automation: The use of robots and automation in fabrication processes is on the rise, leading to increased productivity and reduced labor costs. Collaborative robots (cobots) are becoming more common, working alongside humans in manufacturing environments.

-

Space Fabrication: As humanity explores space and establishes a presence beyond Earth, in-space fabrication and 3D printing will be critical for creating structures, tools, and equipment in extraterrestrial environments.

In conclusion, the future of fabrication holds great promise, with advancements in technology and materials enabling more efficient, sustainable, and customizable production. These developments will impact a wide range of industries, from aerospace and healthcare to consumer goods and construction, and will continue to shape the way we design and produce products in the coming years. For more information contact us today!